Pneumo-electronics

Pneumo-electronic measurement is performed by means of compressed air at constant pressure. The air is used in a circuit in which transducer elements are suitably positioned to convert the distance between a target position and a reference point into an electrical signal. With this technology, dimensional and geometric measurements of a part can be performed.

- Pneumo-electronic measurement has the following advantages:

- It is ideal for measuring small holes

- It is suitable for measuring dimensions with very small tolerances, achieving a measurement resolution down to 0.01µm in the electronic unit

- Geometrical and dimensional measurements are taken without direct contact with the workpiece

Operating principle

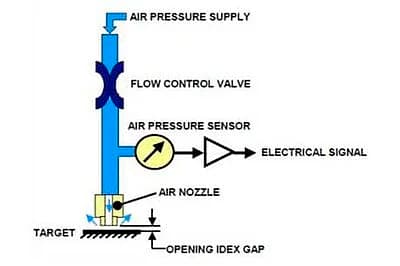

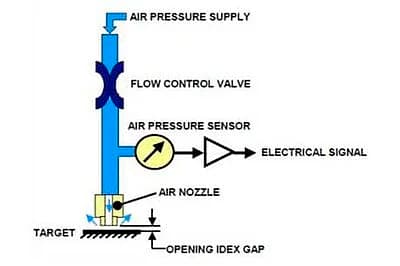

Pneumo-electronic technology is based on the pressure divider principle: it consists of a pneumatic circuit with compressed air, which has the following characteristics

Air supply at constant pressure

Flow control valve to generate a pressure drop

Air pressure sensor to detect the intermediate pressure

An air nozzle positioned at a certain distance from the target to create a GAP opening index

The dimensional variation of the surface to be analysed generates a GAP variation that produces an intermediate pressure variation. This makes the trends directly proportional to the ratio between the equivalent sections of the flow control valve and the GAP.

The air pressure sensor converts this variation into an electrical signal variation.

Lorem ipsum

The sun dipped below the horizon, casting a warm golden glow across the tranquil landscape. Birds chirped softly, their melodies blending harmoniously with the gentle rustling of leaves in the breeze. As twilight settled, a sense of calm enveloped the scene, inviting reflection and peace.